In the realm of modern manufacturing, robotics plays a pivotal role in revolutionizing production processes and enhancing efficiency. With advancements in technology, robots have become indispensable assets in streamlining operations and ensuring precision.

According to recent research by 67%, the adoption of robotics in manufacturing has surged by 23%, reflecting its growing significance in the industry.

In this blog, we will delve into the various ways robotics are transforming manufacturing, driving productivity, and unlocking new possibilities for businesses.

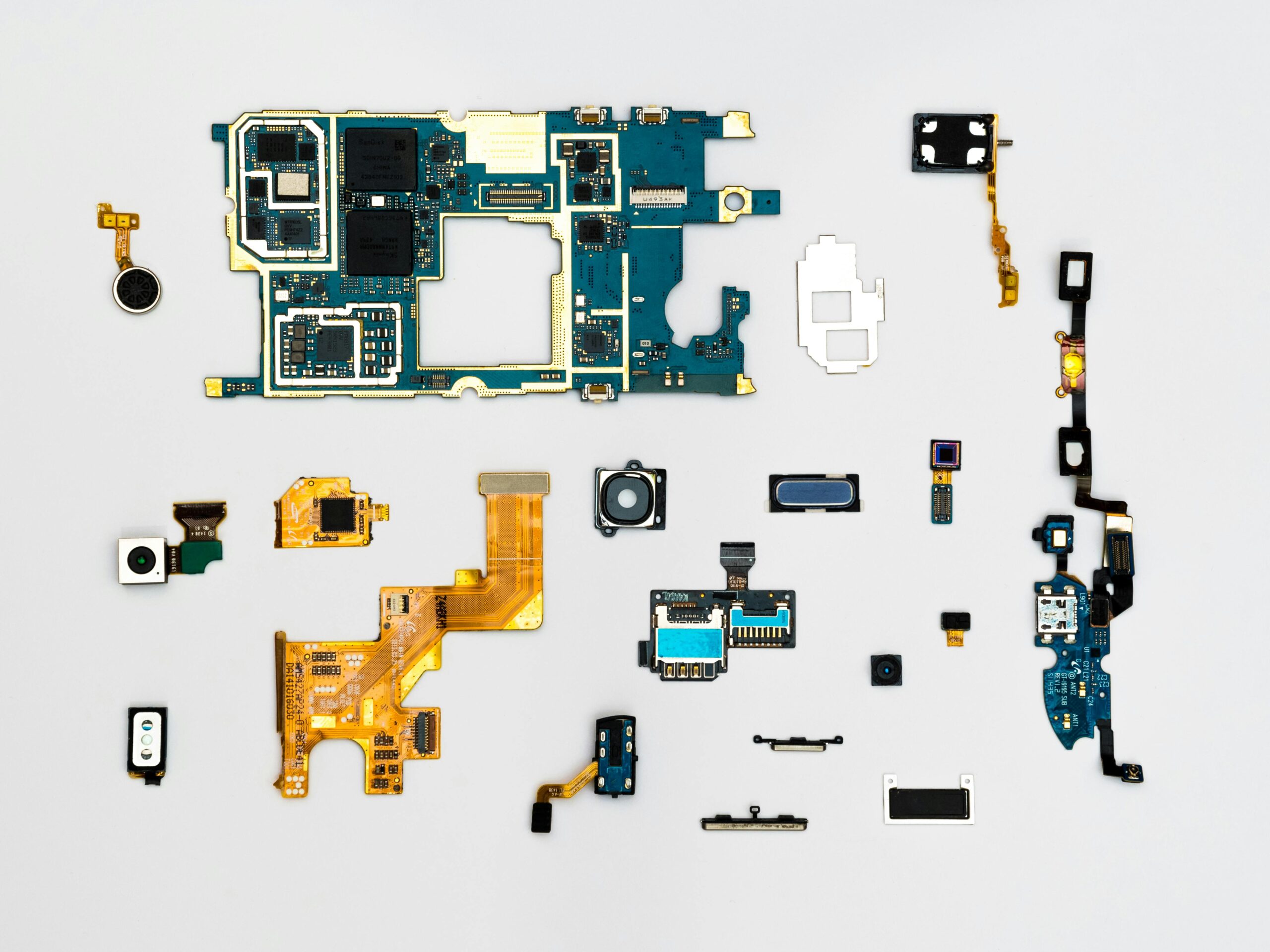

Robotics Integration in Manufacturing Processes:

One of the primary areas where robotics excels in manufacturing is automation. Robots equipped with advanced sensors and programming can perform repetitive tasks with unparalleled accuracy and speed. From assembly lines to material handling, robots optimize production workflows, minimizing errors and reducing cycle times. The seamless integration of robotics into manufacturing processes leads to significant cost savings and enhanced productivity.

Enhanced Quality Control:

Quality control is paramount in manufacturing to ensure consistency and meet stringent standards. Robotics technology offers precise inspection capabilities, detecting defects and deviations with exceptional precision. Through machine vision systems and sensors, robots can identify imperfections in real-time, enabling prompt adjustments and minimizing waste. As a result, manufacturers can deliver high-quality products consistently, bolstering customer satisfaction and brand reputation.

Flexibility and Adaptability:

In today’s dynamic market landscape, manufacturing agility is essential for staying competitive. Robotics empower manufacturers with flexibility and adaptability to respond swiftly to changing demands and market trends. Unlike traditional machinery, robots can be reprogrammed and reconfigured to perform different tasks, offering versatility in production setups. This agility enables manufacturers to optimize resource utilization, minimize downtime, and seize new opportunities with ease.

Safety and Ergonomics:

Safety is a top priority in manufacturing environments, and robotics contribute significantly to enhancing workplace safety and ergonomics. By automating hazardous tasks and lifting heavy loads, robots reduce the risk of accidents and injuries for human workers. Collaborative robots, or cobots, work alongside human operators, providing assistance and support in various tasks. This collaborative approach improves efficiency while ensuring a safer and more ergonomic work environment.

Data-Driven Decision Making:

The integration of robotics in manufacturing generates vast amounts of data, providing valuable insights for decision-making and process optimization. Through sensors and connectivity features, robots capture real-time production data, enabling manufacturers to monitor performance metrics and identify areas for improvement. Analyzing this data allows for predictive maintenance, proactive problem-solving, and continuous refinement of manufacturing processes.

Conclusion:

In conclusion, robotics revolutionizes manufacturing by optimizing production processes, enhancing efficiency, and driving innovation. As businesses strive to stay ahead in a competitive market landscape, embracing robotics technology becomes imperative for sustainable growth and success. At Coding Brains, we understand the transformative power of technology in manufacturing. As a leading software development company, we specialize in developing cutting-edge solutions tailored to meet the unique needs of manufacturing businesses. Partner with Coding Brains to harness the full potential of robotics and propel your manufacturing operations to new heights of excellence.

Leave a Reply